Custom Powder Coating

For Metal Surfaces

Custom Powder Coating

For Metal Surfaces

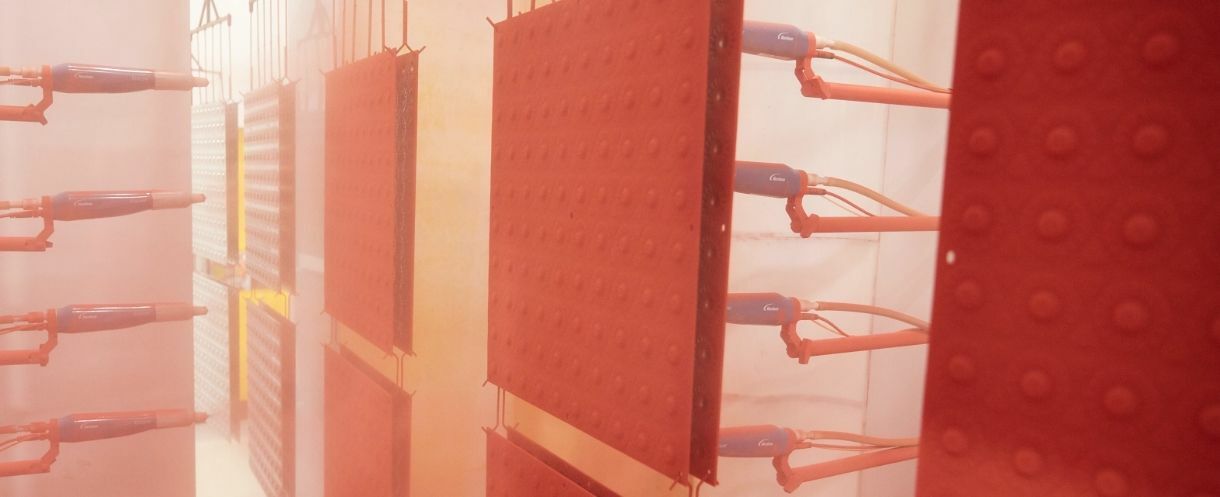

TufTile provides premium powder coating services for commercial and industrial applications. Energy-efficient and highly automated, our state-of-the-art technology was designed by leading pioneers in powder coating systems.

Our team of technicians bring more than 25 years expertise in powder coating metal surfaces, pigment formulation, application, and performance testing.

Protect and preserve the

quality, performance, and

longevity of metal surfaces.

Capabilities

- Accommodates small and large format parts up to 60" x 48" x 12"

- Quickly adjust line speeds to meet production needs

- Standard and custom matched colors

- Smooth or textured finish

- Rapid turnaround with flexible MOQ

Advantages

- 6-stage wash station with zirconium rinse for superior bonding and corrosion resistance

- Optional epoxy base coat

- No solvents or VOCs

- Start-to-finish in just 2 hours

Benefits

- Durable high-performance finish protects against color fading

- Resists chipping, peeling, and most chemicals

- Withstands harsh environments

- Color customization in over 100 colors and pigments

- Environmentally friendly

Our Process

-

Metal components are hung

on monorail system for timed

control of process -

Detergent wash

removes oil, debris, and

other contaminants -

pH controlled

and reverse osmosis rinse

removes residue -

Zirconium rinse prevents

corrosion and preps surface for

powder coat bonding

WASTE WATER TREATMENT

Water is recycled, purified, and reused

-

First drying oven

removes all moisture

from wash process

-

High pigment transfer for

a uniform color build -

Quality checks

conducted before, during,

and after process

-

A final cure crosslinks

metal surface to powder coated

finish for superior adhesion

Contact Us

We are driven by our commitment to produce high-quality products that exceed customer expectations. Contact us today to discuss your powder coating needs.

About Us

Sustainable Solutions Since 2008

Founded in 2008, TufTile® began with a single product marketed under the Tuf-Tite® brand. Today, TufTile has grown to a 200,000 square foot, ISO9001 certified facility located in Lake Zurich, Illinois. Our modern and highly automated manufacturing equipment, in-house powder coating system, on-site warehouse and distribution center allow for any size order that is ready to ship.